Super Clear EVA Film For Safety Glass Laminating Industry

| Product Details | |

|---|---|

| Brand | Super Clear EVA Film |

| Serial Number | GS-TC |

| Country of Origin | China |

| Certificate | SGS, ROHS |

| Payment & Shipping Terms | |

|---|---|

| Price Quote | To be agreed |

| Minimum Order | 1 sqm |

| Average Delivery Time | 5-7days |

| Payment Method | T/T, L/C, Paypal, Credit Card, West union, etc. |

| Package Details | Woven bags, Wooden cases, Pallets |

| Ability to Supply | 100000 sqm per month |

Super Clear EVA Film For Safety Glass Laminating Industry - 0.38mm, 0.50mm, 0.76mm, 1.0mm, 1.14mm

Super clear EVA film stands for Ethylene Vinyl Acetate (EVA) film, a copolymer resin used in the production of laminated safety glass as the interlayer sandwiched between two pieces of glass. The main function of the interlayer is to stick the two pieces of glass together, in order to make the sandwiched glass safer and more secure.

GS-TC series (super clear with no EVA overflow) is made of modified plastic material by special processing. It has the advantages of no overflow at the edge, high toughness, high transparency, high bonding strength, high elongation, and good low-temperature resistance. It is an ideal bonding material for laminated safety glass. This product is widely used in the compound of safety glass, such as guardrail, staircase handrails, sunlight room, and so on.

Available Standard 5 Thicknesses:

0.38mm, 0.50mm, 0.76mm, 1.00mm, 1.14mm

| Items | Model No. | Color | Thickness (mm) | Width (mm) | Length Per Roll (M) | Remarks |

| Super Clear Series (no glue overflow) | GS38TC | Super Clear | 0.38 | 2400 | 100 | Outdoors & Indoors |

| GS50TC | 0.50 | 900~2500 | 80 | |||

| GS76TC | 0.76 | 900~2500 | 50 | |||

| GS100TC | 1.00 | 2000~2500 | 40 | |||

| GS114TC | 1.14 | 2000~2500 | 40 |

* Custom width and length are both available from us.

Super Clear EVA film is made out of macromolecule material and it performs excellently in bonding strength, heat resistance, cold resistance, humidity resistance, and tensile strength in laminated security glass. It has been partly used as a substitute for PVB film in laminated safety glass, laminated art glass, laminated colorful glass.

Super clear EVA glass interlayer film is not adhesive before heating. After heating, it melts and reacts. In the production of laminated glass with EVA interlayer, no autoclave, roller press, airbag, or vacuum rubber ring is required. Our super clear EVA film can be processed under normal climatic conditions, no clean room with climatic control is required. And the producing machine of laminated glass with EVA Film is less costly and easier to process.

Technical parameters of GS-TC series (Ethylene Vinyl Acetate Film)

| Item | Unit | Value |

| Melting point | ℃ | 68 |

| Density | g/cm3 | 0.958 |

| Glass transition temp | ℃ | -45 |

| Tensile strength | Mpa | 44.6 |

| Elongation (before laminated) | % | 842 |

| Degree if crosslinking | % | 85 |

| Water absorption | % | ≤0.1 |

| Haze | % | 0.22 |

| Light transmittance | % | 91.9 |

| Bonding strength (to glass) | N/10mm | 112 |

| UV reduction | % | ≥99 |

| UV aging reistance (15Kwh/m2, 290~385nm) | Light transmittance% | 89.2 |

| Damp&heat aging resistance(85℃ 85% humidity 1000h) | Light transmittance% | 88.6 |

| Impact resistance against shot-bag (GB-15763.3-2009) | 1200MM | Qualified |

| Ball impact resistance (GB-15763.3-2009) | 4800MM | Qualified |

| Humidity aging resistance (GB-15763.3-2009) | / | Qualified |

Processing instruction for Super Clear Ethylene Vinyl Acetate (EVA) Film

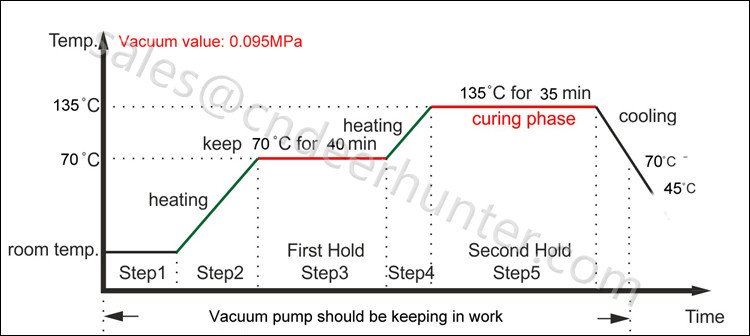

1: Seal the silicone vacuum bag. Before the silicone bag shelf being pushed into the oven, start the vacuum pump to vacuum for 10 minutes at room temperature. See “Step1”. The purpose is to check whether the silicone bag is leaking out or not. And the vacuum value should at least be set 0.095Mpa.

2: Push the silicone bag shelf into the oven, then set the parameters of temperature and time. Start increasing the temperature up to 70℃ at a rate of 2-3℃/min slowly. See “Step2”. Keep the temperature at 70℃ for 40minutes. See “Step3”.

(Notes: following the instructions that the EVA FILM MANUFACTURERS give to you, the parameters may be different for different manufacturers). Because it takes time for the heat transfer through the silicone bag, so the temperature the detector gets may be different from the real temperature of the laminated glass.

3: Go on increasing the temperature up to 135℃ at a rate of 2-3℃/min slowly. See “Step4”. Keep the temperature at 135℃ for 35minutes. See “Step5” curing phase.

4: Stop heating. Wait till the temperature is lower than 70℃, then open the oven door and pull out the silicone bag shelf to help to cool. But don’t open the silicone bag or let cold water touch the laminated glass.

5: After the temperature is lower than 45℃, now you can open the silicone bag and check the laminated glass.

EVA laminating film for glass industry

1). Curtain wall

2). Stair rail, skylight, awning, balcony guardrail

3). Auto glass.

4). Bullet-proof laminated glass for banks, government building, hospital, store counter, villa

5). Interior partition/decorative.

6). Furniture, tabletop and so on.

Not Sure Where To Start?

Before purchasing EVA films for laminated glass, customers need to know as follows:

1: Please let us know your application (indoors or outdoors); then we can recommend the very right thickness and model for you.

2: Free samples of EVA films are available from us.

3: To get our latest Catalog – EVA Films For Laminated Safety Glass, or please me by email sales@cndeerhunter.com

You'd Like To Learn More

Become A Partner

We are well prepared to work with you tegether!

No matter who you are and what you do, a wholesaler, distributor or end-user, we are always looking out for new partnership chances. Submit an application today and our sales team will get back to you as soon as possible within 24 hours and help you select the right silicone bag you want.

- fullchance100

- 0086 13823789007

- exporting@cndeerhunter.com