Vacuum Press Membranes For Coating of PVC foil, Veneer Pressing, Wood Bending And Composites

| Product Details | |

|---|---|

| Brand | Deer Hunter |

| Serial Number | DH2211 |

| Country of Origin | China |

| Certificate | SGS, ROHS |

| Payment & Shipping Terms | |

|---|---|

| Price Quote | To be agreed |

| Minimum Order | 1PC |

| Average Delivery Time | 5-7days |

| Payment Method | T/T, L/C, Paypal, Credit Card, West union, etc. |

| Package Details | Carton boxes, Wooden cases, Pallets |

| Ability to Supply | 100000kgs per month |

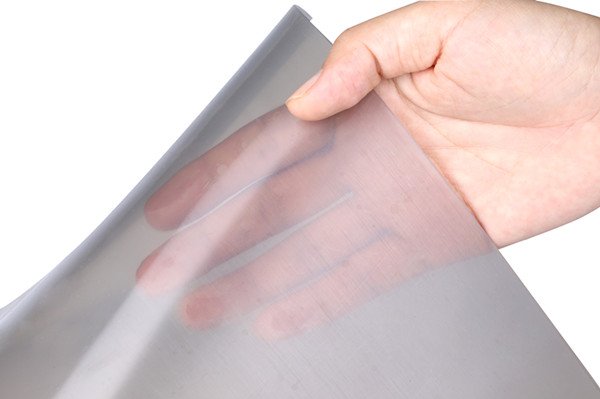

Vacuum Press Membranes For Woodworking And Thermoforming

As technology progresses, DH2211 silicone membrane rubber sheet delivers high performance and long life span at extreme temperatures. It has been the ideal vacuum press membrane material for bending, laminating and veneering used in wood door vacuum press table machines. For DH2211 is growing popularity among customers all over the world, China Deer Hunter has been regarded as one of the leading silicone membrane suppliers and manufacturers. Our silicone vacuum membranes are mainly used in the woodworking, glass and solar industries.

Silicone membrane sheet DH2211 with high tear resistance is designed for pressing and forming workpieces at high temperatures. An example may be forming of materials like Corian, LG Hi-Mac, etc. Temperature resistance of the sheeting is 250°C and its elasticity to 860%. The sheeting widths are available from 500mm to 3800mm. We can supply customized silicone rubber membrane in many dimensions.

Below are some sizes that our customers ever purchased from us.

Size | Surface |

2300 x 23000 x 2mm | smooth/smooth |

3200 x 3400 x 2mm | smooth/smooth |

2000 x 20000 x 2mm | smooth/smooth |

1500 x 12200 x 2mm | smooth/smooth |

1500 x 15200 x 3mm | smooth/smooth |

1800 x 10000 x 3mm | smooth/smooth |

2000 x 6700 x 3mm | smooth/smooth |

1600 x 18000 x 1mm | smooth/smooth |

1750 x 3400 x 3mm | smooth/textured |

Vacuum Forming Membranes Facts

* Manufactured in a range of thicknesses from 1mm to 4mm

* Max width up to 3.8m wide on selected products

* Shore A hardness from 40-50

* Thermally stable over a wide range of temperatures (-60°C to 250°C)

* Standard color – Gray transparent

* Surface can be smooth/smooth(THK 1mm/2mm/3mm) and smooth/textured(THK 2mm/3mm)

Area of application

– Membrane vacuum presses

– PVC foiling

– Veneering by natural veneer

– Bonding laminates

– Solid surface solid-state mods such as. Corian, Staron etc.

– Thermoplastic moldings of PVC, Plexi elements

Veneering and Laminating

Coating of Simple Profiles

Wood Bending

3D Coating

Technical Data

Type | Silicone Membrane Sheet For Vacuum Press |

Thickness, mm: | 1, 2, 3 |

Tolerance of thickness, mm: | + / – 0,4 |

Width, mm: | 500~3800 |

Density, g/cm3 : | 1,25 + / – 0,02 |

Working temperature, max °C: | 250 |

Tensile strength, MPa: | 11.5 |

Hardness, SHA: | 45 + / – 5 |

Flexibility, %: | 860 |

Tear strength, N/mm : | 45 |

Colour: | Gray transparent |

Surface: | Smooth/Smooth Smooth/Textured |

Technical Data Sheet – DH2211 Silicone Membrane Sheet (Smooth/Textured) |

Why Choose Deer Hunter Silicone Membrane Sheets & Rolls?

Our vacuum press membranes are unrivalled. Being the manufacturer allows us to formulate, manufacture and supply the best quality silicone sheeting and rolls in the industry, at competitive prices.

With a vast array of silicone grades available, we work closely with our customers to design and provide silicone solutions to many applications and specific requirements. Our in-house silicone compounding facility gives us a competitive advantage and is equipped with some of the largest state of the art processing systems in China. It currently processes in excess of 5000 tonnes of silicone rubber each year whilst maintaining full quality control and material integrity at every stage of the process. This means the highest quality is guaranteed and something that we represent globally.

Using the latest state of the art processing equipment, our vacuum press membranes are manufactured to the highest quality on calendered sheeting lines equipped with automated laser gauges for the tightest dimensional controls.

You'd Like To Learn More

Become A Partner

We are well prepared to work with you tegether!

No matter who you are and what you do, a wholesaler, distributor or end-user, we are always looking out for new partnership chances. Submit an application today and our sales team will get back to you as soon as possible within 24 hours and help you select the right silicone bag you want.

- fullchance100

- 0086 13823789007

- exporting@cndeerhunter.com