Silicone Membrane Sheet For Solar PV Panel Lamination - 2nd Generation

| Product Details | |

|---|---|

| Brand | Deer Hunter |

| Serial Number | The 2nd Gen |

| Country of Origin | China |

| Certificate | SGS, ROHS |

| Payment & Shipping Terms | |

|---|---|

| Price Quote | To be agreed |

| Minimum Order | 1 sqm |

| Average Delivery Time | 5-7days |

| Payment Method | T/T, L/C, Paypal, Credit Card, West union, etc. |

| Package Details | Woven bags, Wooden cases, Pallets |

| Ability to Supply | 100000 sqm per month |

Silicone Membrane Sheet For Solar PV Panels Lamination

Deer Hunter’s grey silicone membrane sheet is well-known throughout the industry for its consistency and durability. With high tear and temperature resistance, these silicone membrane sheets are in use worldwide on the full variety of solar PV panels laminators.

The 2nd Gen grey silicone membrane sheet is our original & most popular silicone membrane sheet quality – combining hi-elongation, good life cycle performance under controlled environments and very competitive pricing. It’s available with both sides smooth or single-sided fabric impression surface finish.

Availability and technical Features:

- Seamless (no weak point)

- Standard thickness 4 mm available

- Long life time resulting in increased service

- High stability

- Compression and temperature resistant + 250 °C

- Low-priced

- Colour gray

- 1 Ply premium grade aramid fabric reinforcement

Technical Data:

Material | Silicone |

Color | Gray |

Surface | Smooth/Smooth or Smooth/Textured |

Reinforcing Layer | 1 Ply Premium Grade Aramid Fabric |

Hardness | 70+/-2 Shore A |

Density | 1.25 ± 0.05g/cm3 |

Tensile Strength | 12.5MPa |

Tear Strength | 48N/mm |

Temperature resistance | 250°C |

Elongation | 600% |

Compression Set | 2% |

Resilience | 30% |

The 2nd Gen 4mm silicone rubber membrane sheet is our well-proven standard product.

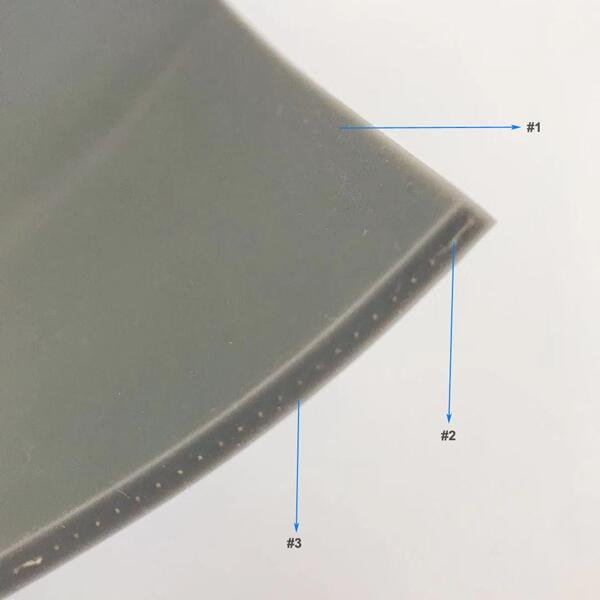

Structure

1# Grey silicone

2# 1 Ply premium aramid fabric reinforcement

3# Gray silicone

Standard dimensions

Width: Max up to 3800mm

Material thickness: 4 mm

Fabrication even beyond the standard width

The Second Generation lamination silicone membrane sheets are specially designed for the solar module lamination process.

Our silicone membrane sheets are enhanced to achieve higher laminator uptime and decreased running costs.

Starting from base silicone materials, our membrane material formulation and its manufacturing process have been optimized to offer a superior product. Our solar module lamination membranes are available up to 3800 mm wide without a splice. This offers module manufacturers the advantage of not having seam marks visible on their back sheets created during the lamination process.

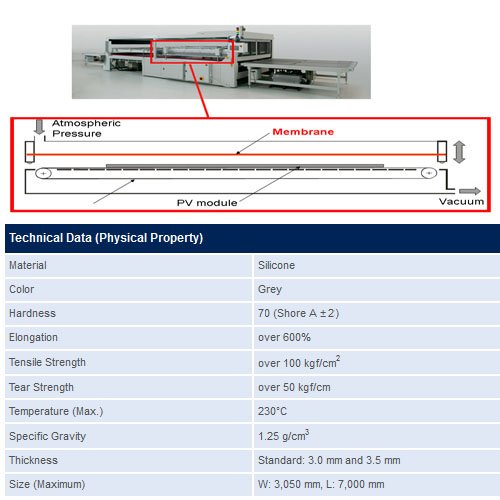

Technical Data Sheet – The 2nd Generation Silicone Membrane Sheet |

Do you need a wide silicone membrane sheet without a splice?

As a leading silicone membrane supplier in China, Deer Hunter’s seamless lamination silicone membrane sheet enables photovoltaic module makers to produce panels up to 3800mm wide with no seam marks visible on the back sheet.

Do you prefer smooth/smooth or smooth/textured?

We find the question of surface finishes interesting – but in conclusion, we see no evidence that one option is better than another. Common sense says that a fabric impression will provide a natural venting path to aid release, especially in hot/sticky conditions. Most of our customers do prefer fabric impression 1 side and smooth 1 side. The physical properties of the material will be exactly the same irrespective of colour or surface finish – these do not change.

Silicone Membrane Sheet For Solar Lamination

The lamination process involves pumping the air out of the module layers in a vacuum chamber, heating the layers to melt the encapsulant, and pressing the layers together with a flexible diaphragm or membrane to embed the cells in the encapsulant and adhere the front and back sheets. The flexible membrane is attached to the top of the vacuum chamber, and a set of valves allows the space above the diaphragm to be evacuated.

There are 3 main purposes of the grey silicone membrane sheet in the vacuum process:

- To exert a uniform pressure throughout the solar lay-up.

- Removal of moisture, solvents and volatiles from curing composite layers.

- Allow encapsulant material to flow evenly throughout solar cell lay-up.

Photovoltaic modules need to withstand harsh environmental conditions for long periods – 25 years or more. One of the keys to module longevity and reliability is the lamination process, which needs an excellent grey silicone membrane sheet to encapsulate solar cells while attaching front and back protective sheets.

You'd Like To Learn More

Become A Partner

We are well prepared to work with you tegether!

No matter who you are and what you do, a wholesaler, distributor or end-user, we are always looking out for new partnership chances. Submit an application today and our sales team will get back to you as soon as possible within 24 hours and help you select the right silicone bag you want.

- fullchance100

- 0086 13823789007

- exporting@cndeerhunter.com