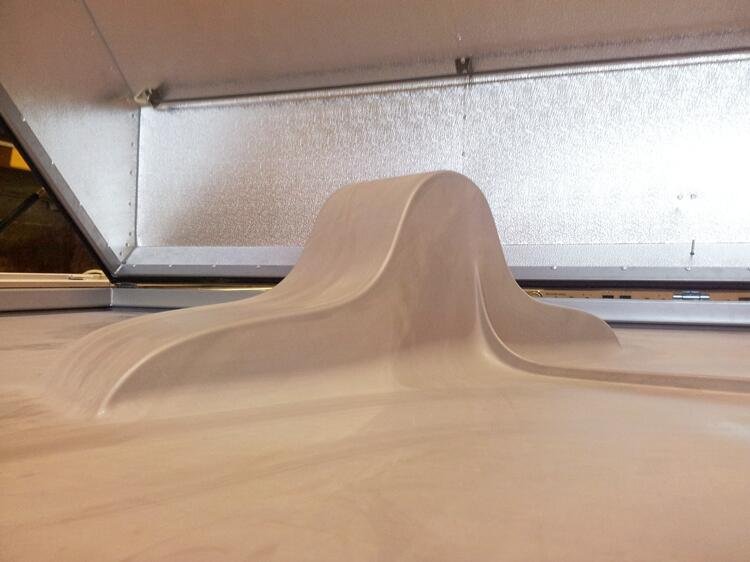

What are silicone vacuum membranes?

Silicone vacuum membranes are a superior grade of silicone that offers more excellent elongation and abrasion resistance than standard, as well as a longer life expectancy. With widths available up to 3800mm and lengths to suit your specific needs, you can be ensured to receive the ultimate product suited for your woodworking purpose.

It can be found in thicknesses between 1mm and 3mm, providing a versatile solution for any application.

Deer Hunter’s vacuum forming membranes are used in many sectors among which:

- Wood veneering

- Glass lamination

- Dye sublimation process

- Photovoltaic panel lamination

- Solid surfaces thermoforming

- Composite materials vacuum lamination

Deer Hunter strives to produce superior silicone membrane sheets for woodworking and thermoforming industries, collaborating with wood and furniture companies, as well as membrane press and vacuum forming manufacturers. By doing so, the much sought-after brand is able to provide top-notch quality in all their products.

You'd Like To Learn More

Silicone Membrane Sheets For Vacuum Press

Deer Hunter is a professional silicone sheet manufacturer in China. Our silicone membranes feature high tear strength and come in all sizes, making them perfect for vacuum forming applications across a variety of industries, such as aerospace, automotive and composite.

Our experienced specialists are available to offer additional advice tailored to the customer’s needs. If you’re looking for durable and high temp silicone vacuum membranes, Deer Hunter has what you need!

Silicone Vacuum Sheets FAQs

Need answers? Look no further. Here you’ll find an FAQ section with the most commonly asked questions from our customers. If your query remains unaddressed, don’t hesitate to get in touch with us for more information.

(1) What are your standard colors?

– Our default color is transparent grey. No matter the color, it does not affect the quality of the material, making it easier to distinguish between different material durometers and suppliers.

(2) Can you do other colors?

– Some of our customers have differing preferences when it comes to color mixtures. Some prefer certain colors more strongly than others. Plus, we offer a variety of tints such as translucent, gray, blue, red and more.

(3) What’s better, a smooth or a textured surface?

– It depends on what works best for your application. Some customers need a smooth surface for high-gloss finishes. Some prefer a textured or matte surface toward the heating plate for improved heat transfer. Some use the textured or matte surface down toward the foil to get a slightly different sheen on their foil or to prevent darker foils from scuffing.

(4) We call it a sheet, but other suppliers keep calling it a membrane and now you’re telling me some others call it a diaphragm! What’s the real name?

– Just call it whatever you like, and we’ll know what you mean. Although there are various names for the same product, we are able to figure out your needs and help you get the best product for your application.

(5) Do you have a technical data sheet to download to compare with the other silicone sheet suppliers?

– Please check below.

| TDS – DH2211 Smooth/Smooth Silicone Membrane Sheet For Vacuum Press | |

| TDS – DH2211 Smooth/Textured Silicone Membrane Sheet For Vacuum Press |

Our silicone vacuum membranes are highly versatile products, known for their excellent durability and resistance. They are perfect for vacuum forming solid surfaces, furniture production, and veneer lamination of cabinet doors. Their high flexibility and abrasion resistance make them a preferred choice among many industries.

Become A Partner

We are well prepared to work with you tegether!

No matter who you are and what you do, a wholesaler, distributor or end-user, we are always looking out for new partnership chances. Submit an application today and our sales team will get back to you as soon as possible within 24 hours and help you select the right silicone bag you want.

- fullchance100

- 0086 13823789007

- exporting@cndeerhunter.com