Silicone Rubber Membrane For Solar Modules Lamination - The 5th Generation

| Product Details | |

|---|---|

| Brand | Deer Hunter |

| Serial Number | The 5th Gen |

| Country of Origin | China |

| Certificate | SGS, ROHS |

| Payment & Shipping Terms | |

|---|---|

| Price Quote | To be agreed |

| Minimum Order | 1 sqm |

| Average Delivery Time | 5-7days |

| Payment Method | T/T, L/C, Paypal, Credit Card, West union, etc. |

| Package Details | Woven bags, Wooden cases, Pallets |

| Ability to Supply | 100000 sqm per month |

Silicone Rubber Membrane For Solar Panels Lamination

Silicone rubber membrane, also called silicone rubber sheet or silicone diaphragm, is applied for the lamination process of solar modules. During the laminating period, silicone rubber membranes transfer the laminator’s temperature and pressure to modules. The silicone membrane works at least 10,000 laminating cycles with good EVA-resistant ability, even more than 10,000 times for some solar laminators.

The 5th Gen is an extraordinary type of rubber sheets, specially developed rubber membrane consisting of a silicone backing material and a unique covering layer. This covering layer is extremely resistant to outgassing* and related decomposing processes of EVA films. This makes our membrane particularly durable and increases your machine running times.

Product descriptions and advantages

- 1 piece seamless sheet width up to 3800mm wide (no weak joints or marks on lay-up)

- Good cycle life - more than 10,000 cycles

- Good reusability&durability when exposed to high pressures&elevated temperatures: +250°C

- Special fluorine covering layer (black) on silicone backing (grey)

- Bond of the two layers cannot be separated mechanically

- Black covering layer is resistant to decomposing EVA outgassing* during the lamination process

*Outgassing:

refers to unwanted chemicals that are usually a bi-product of the process and temperature. These acidic fumes are emitted from adhesive or other components and can lead to corrosion of the Diaphragm/Membrane. This corrosion manifests itself in surface degradation (cracks) + excessive stretching & sagging.

How long should a membrane last?

This is really very subjective as operating conditions and controls can be very different from company to company. Whilst we quote a guide of 10,000 cycles, due to the many elements beyond our control in the installation & operating environment, it is very difficult to guarantee an exact life cycle.

Technical Data:

Material | Silicone/FKM | |

Color | Grey/Black | |

Surface | Smooth/Textured | |

Reinforcing Layer | 1 Ply Premium Grade Aramid Fabric | |

Hardness | EVA Resistant Working Surface (Black FKM) | Buffering Surface (Grey Silicone) |

70+/-2 Shore A | 60+/-2 Shore A | |

Density | 1.95 ± 0.05g/cm3 | 1.25 ± 0.05g/cm3 |

Tensile Strength | 14MPa | 8.5MPa |

Tear Strength | 45N/mm | 30N/mm |

Temperature resistance | 250°C | 250°C |

Elongation | 180% | 600% |

Compression Set | 4% | 4% |

Resilience | 8% | 25% |

Silicone Rubber Membrane For Solar Modules Lamination

It has an EVA resistant fluorine laminated surface with additional fabric reinforcement.

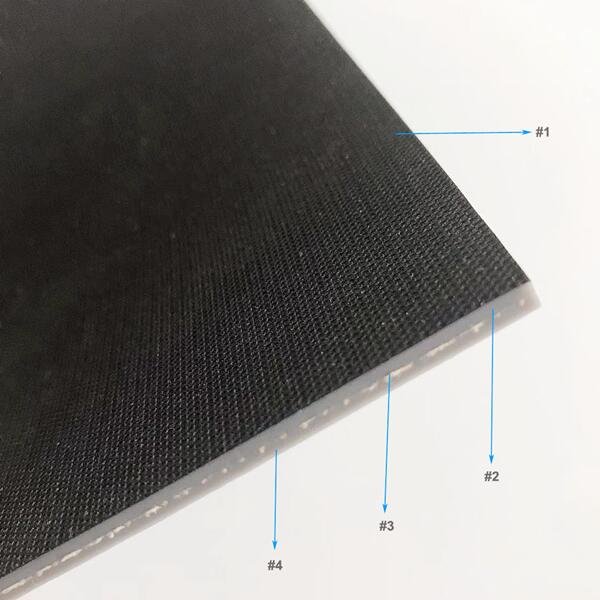

Structure

1# Black EVA resistant fluorine – working layer

2# Grey silicone

3# 1 Ply premium aramid fabric reinforcement

4# Grey silicone – buffering layer

Standard dimensions

Width | Max up to 3800mm |

Material thickness | 4 mm or 3mm |

Feature | Fabrication even beyond the standard width |

Technical Data Sheet – The 5th Generation Silicone Rubber Membrane |

During the lamination/encapsulation process of EVA volatile outgassing occurs. Outgassing refers to unwanted chemicals that are usually a bi-product of the process and temperature. These acidic fumes are emitted from adhesive or other components and can lead to corrosion of the Sheets. This corrosion manifests itself in surface degradation (cracks) + excessive stretching and sagging.

Deer Hunter’s 5th gen silicone rubber membrane is a hybrid material that resists the deterioration caused by EVA outgassing. In addition, it is a really tough material with both tensile strength and tear resistance higher than traditional Membranes materials.

It has very tight elongation features – resistant to excessive stretching and sagging. Customers feedback indicates that our silicone sheets may give up to 50% longer life than some traditional Diaphragm materials – obviously dependent upon the type of module, encapsulant and conditions.

Silicone rubber membrane for the lamination of solar panels, Deer Hunter can choose from a variety of laminator brands and types. Depending on the solar module production line requirements, a solar panel laminator from 3S, Meier, Bürkle, Komax, Electro Solar, or others is integrated.

Widely-used sizes of silicone rubber membranes from our regular customers as below:

| Country | Sizes |

| USA | 4mm * 2550 * 6550 4mm * 2850 * 5550 4mm * 3050 * 4850 |

| Mexico | 4mm * 2600 * 4100 4mm * 2730 * 5870 4mm * 3200 * 5200 |

| Morocco | 4mm * 2000 * 2400 |

| India | 4mm * 2550 * 5720 4mm * 2575 * 4675 |

| Jordan | 4mm * 2760 * 4960 |

| Turkey | 4mm * 2650 * 4730 4mm * 2750 * 4100 4mm * 2850 * 5050 3mm * 3110 * 4460 |

| Vietnam | 4mm * 2800 * 4100 |

| Philippines | 4mm * 2500 * 4100 |

| South Korea | 3mm * 2755 * 4925 |

| Germany | 4mm * 2410 * 4500 |

| Poland | 4mm * 2200 * 3700 4mm * 2700 * 4500 |

*Our silicone rubber membrane can be cut to your dimensions and delivered to you without any damage.

You'd Like To Learn More

Become A Partner

We are well prepared to work with you tegether!

No matter who you are and what you do, a wholesaler, distributor or end-user, we are always looking out for new partnership chances. Submit an application today and our sales team will get back to you as soon as possible within 24 hours and help you select the right silicone bag you want.

- fullchance100

- 0086 13823789007

- exporting@cndeerhunter.com