Silicone Rubber Sheets For Woodworking Membrane Vacuum Presses - DH2211

| Product Details | |

|---|---|

| Brand | Deer Hunter |

| Serial Number | DH2211 |

| Country of Origin | China |

| Certificate | SGS, ROHS |

| Payment & Shipping Terms | |

|---|---|

| Price Quote | To be agreed |

| Minimum Order | 1PC |

| Average Delivery Time | 5-7days |

| Payment Method | T/T, L/C, Paypal, Credit Card, West union, etc. |

| Package Details | Carton boxes, Wooden cases, Pallets |

| Ability to Supply | 100000kgs per month |

Silicone Sheets For Vacuum Presses

Are you looking for a reliable supplier for vacuum forming silicone sheets? Look no further than Deer Hunter! We’re the experts in manufacturing these products, which are used in applications ranging from veneer pressing and wood bending to thermoforming of solid surface materials and composites.

Silicone vacuum sheets, known also as membranes, diaphragms, bladders, or blankets, are used in woodworking and thermoforming processes. Optimizing the peak performance of vacuum membrane presses is easy with these silicone rubber membranes. Regardless of what name you prefer to call them, these silicone sheets are essential for reaching maximum efficiency.

Improve your business performance with our top-of-the line products. Our extensive selection and specialized expertise make us the perfect partner for choosing the right thickness to suit any application, so let’s get started on bringing success to you.

Thermoforming Silicone Rubber Sheets For Vacuum Press

Silicone vacuum sheets provide an effective solution for 3D lamination, vacuum forming, and membrane pressing in the woodworking, solar energy, solid surface composite and steel-rule die industries. We have partnered with component producers to consistently offer high temperature silicone rubber sheets at an excellent value. With years of expertise, we are proud of our contributions to these industries.

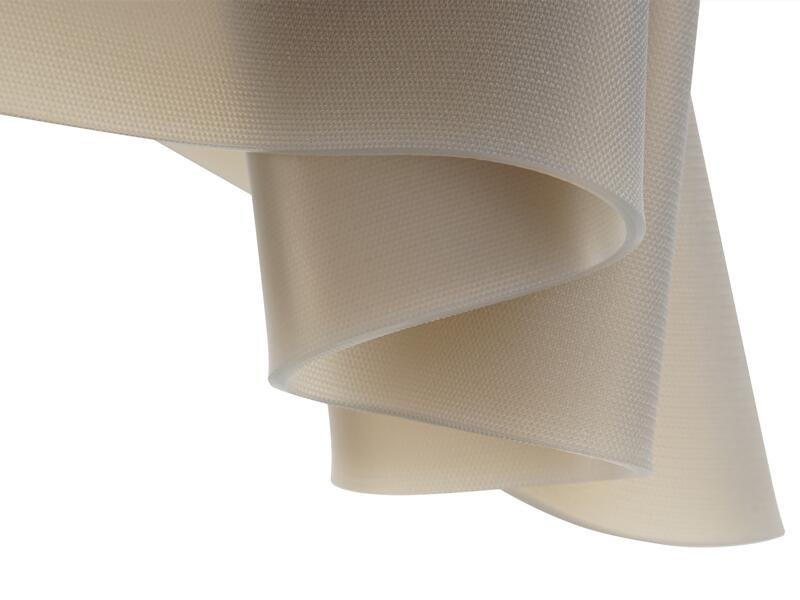

Our silicone membrane sheets are valued world-wide for their consistency and durability. Surfaces are available for smooth/smooth and smooth/textured, ensuring that each customer can find the correct membrane for their woodworking applications.

Building on their success, Deer Hunter continues to research and develop products specific to the various industries they serve.

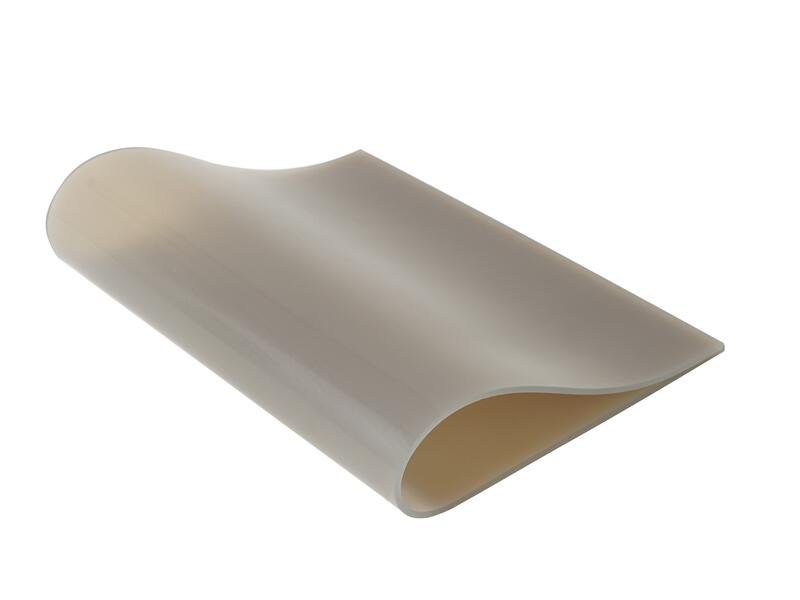

Thickness 1mm silicone vacuum sheet - smooth/smooth

Thickness 2mm silicone membrane sheet - smooth/smooth

Thickness 3mm silicone vacuum membrane - smooth/smooth

Thickness 2mm and 3mm silicone sheet membrane - smooth/textured

Blue Durometer 50A Silicone Rubber Sheet - Textured/Smooth

Vacuum forming silicone sheets for the furniture industry

As to the coating and veneering of furniture, vacuum table presses are mostly the first choice in case of delicate surfaces or complicated models. The result is significantly influenced by the quality of the silicone sheet membranes used in the press so the suitable thickness, the fitting material, and high quality have to be observed.

For years, our high tear strength DH2211 silicone rubber sheeting has been used successfully in the furniture and kitchen industry and combine persistence, abrasion hardness, and heat resistance in one product. So, for example, they are used for veneering of high-gloss furniture panels of kitchens and also to coat counter surfaces made of solid or plywood with scratch-proof or water-repellent materials.

Product Features:

*High tear strength

*High elasticity (860%)

*Improved abrasion resistance

*Ability to withstand puncture damage without catastrophic failure

*Durability and Lifespan

*Developed specifically for use as a vacuum bagging material

*Supplied as standard in Translucent

*Capability to color match if required

*Vacuum presses membranes tolerance allowance – width 3%, length 5%.

Technical Data:

| Model No.: | DH2211 – high tear strength silicone sheet |

| Thickness, mm: | 1, 2, 3 |

| Thickness tolerance, mm: | +/- 0,2 |

| Width, mm: | Max up to 3800mm |

| Length, m: | On request |

| Density, g/cm3: | 1.25 ± 0.05 |

| Tensile strength, Mpa: | 11.5 |

| Hardness, ShA: | 40 ± 5 |

| Elasticity, %: | 860 |

| Tear strength, N/mm: | 45 |

| Working temperature, °C : | from -60 till +230, max +250 |

| Color: | Transparent grey |

| Surface: | Smooth |

| TDS – DH2211 Smooth/Smooth Silicone Sheet For Vacuum Press | |

| TDS – DH2211 Smooth/Textured Silicone Sheet For Vacuum Press |

Area of application

Solar panel laminating, laminating of foil, veneer, production of triplex, thermoforming of solid surface and thermoplastic materials.

Why 3D Lamination?

Amid growing concerns about sustainability and deforestation, 3D Lamination offers many of the aesthetically pleasing advantages of real wood without depleting that natural resource. And with the huge variety of 3D Laminates now available, shapes and surfaces that were once either very expensive or pure fantasy can become reality at affordable prices.

As a result, the demand for quality laminated materials has exploded, with companies around the world looking for quality membrane pressed components to complete their important projects.

Benefits of 3D Lamination

- Flexibility in design

- Cost-Effective

- Prevents Bacterial Growth and Contamination

- Water-Resistant

- Create soft or rounded edges

- Easy to Clean

- Durable

- Good for various commercial applications

Check out our wide range of products we have available and contact us today for a consultation to determine which membrane material is best for your application. We pride ourselves on the ability to provide attentive customer service and timely results to help our clients get the high-quality materials they need for all woodworking projects.

Silicone Sheet Membranes FAQs

Do you have questions about our products or services?

Below are the most commonly asked questions from our customers. If you have additional inquires that are not addressed here, please contact us for more information.

(1) What difference does the color make?

– The color is really just to make it easier to differentiate between different material durometers.

(2) So why do you have some different colors for the same durometer?

– The answer to that is simply “Give the people what they want!” Some of our customers maintain that certain colors work better for them than others in the same mixture. Whenever we can, we’ll accommodate that.

(3) What’s better, a smooth or a textured surface?

– It depends on what works best for your application. Some customers need a smooth surface for high-gloss finishes. Some prefer a textured or matte surface toward the heating platen for improved heat transfer. Some use the textured or matte surface down toward the foil to get a slightly different sheen on their foil or to prevent darker foils from scuffing.

(4) I call it a membrane, but my co-workers keep calling it a sheet and now you’re telling me some others call it a diaphragm! What’s the real name?

– Stop giggling and call it whatever you like, we’ll know what you mean. we’ll know what you mean. Although there are various names for the same product, we are able to decipher your needs and help you get the best product for your application, whether it’s a bladder, diaphragm or any other name your team calls it.

(5) Widely-used sizes of our slicone rubber sheeting from our regular customers?

– Please check below.

| 1600 x 18000 x 1mm |

| 1600 x 12000 x 1mm |

| 1500 x 12200 x 2mm |

| 1500 x 18500 x 2mm |

| 1500 x 18000 x 2mm |

| 1660 x 25000 x 2mm |

| 3000 x 5200 x 2mm |

| 1500 x 12000 x 3mm |

| 1500 x 15200 x 3mm |

| 1500 x 9200 x 3mm |

| 1700 x 12000 x 3mm |

| 1800 x 10000 x 3mm |

| 1800 x 11500 x 3mm |

| 1800 x 13000 x 3mm |

| 1800 x 13200 x 3mm |

| 1850 x 7400 x 3mm |

| 2000 x 6600 x 3mm |

| 2000 x 6700 x 3mm |

| 2000 x 7600 x 3mm |

| 2300 x 4300 x 3mm |

| 3300 x 4900 x 3mm |

| 3500 x 9000 x 3mm |

We are the leading manufacturer & supplier in Asia offering seamless silicone sheets at a width of up to 3500m, made in China. All units beyond this dimension will be joined by a seam. We make our products of thicknesses 1mm, 1.5mm, 2mm, and 3mm. Additionally, we enable you to make your choice of different hardness degrees according to customers’ special requirements.

You'd Like To Learn More

Become A Partner

We are well prepared to work with you tegether!

No matter who you are and what you do, a wholesaler, distributor or end-user, we are always looking out for new partnership chances. Submit an application today and our sales team will get back to you as soon as possible within 24 hours and help you select the right silicone bag you want.

- fullchance100

- 0086 13823789007

- exporting@cndeerhunter.com