Silicone Rubber Sheets For Woodworking Membrane Vacuum Presses - DH2211

| Product Details | |

|---|---|

| Brand | Deer Hunter |

| Serial Number | DH2211 |

| Country of Origin | China |

| Certificate | SGS, ROHS |

| Payment & Shipping Terms | |

|---|---|

| Price Quote | To be agreed |

| Minimum Order | 1PC |

| Average Delivery Time | 5-7days |

| Payment Method | T/T, L/C, Paypal, Credit Card, West union, etc. |

| Package Details | Carton boxes, Wooden cases, Pallets |

| Ability to Supply | 100000kgs per month |

Silicone Rubber Sheets For Vacuum Press

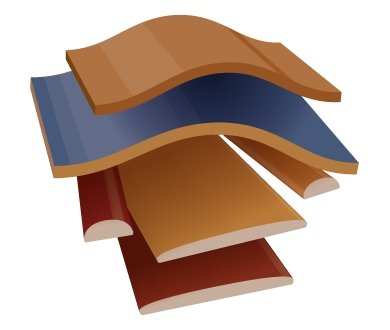

Silicone rubber sheets are widely used in various applications due to their exceptional properties, such as high temperature resistance and elasticity. These sheets are perfect for thermal forming, hot pressing and vacuum forming of solid surfaces, as well as other composite materials. Their versatility ensures that these rubber membranes can be used for multiple areas.

Deer Hunter provides durable, trustworthy silicone vacuum sheets to woodworking businesses around the world. Our silicone is available in hardnesses ranging from soft to firm as well as both smooth and textured surfaces, so customers can find the perfect sheet for their 3D lamination application. At Deer Hunter, we understand that each customer has unique needs, which is why we continually research and develop tailor-made products for specific industry requirements.

Technical Data:

Model No.: | DH2211 – high tear strength | DH2111 – standard tear strength |

Thickness, mm: | 1, 2, 3 | 1, 2 |

Thickness tolerance, mm: | +/- 0,2 | +/- 0,2 |

Width, mm: | Max up to 3800mm | Max up to 2800mm |

Length, m: | On request | |

Density, g/cm3: | 1.25 ± 0.05 | 1.25 ± 0.05 |

Tensile strength, Mpa: | 11.5 | 9.0 |

Hardness, ShA: | 40 ± 5 | 50 ± 5 |

Elasticity, %: | 860 | 480 |

Tear strength, N/mm: | 45 | 30 |

Working temperature, °C : | from -60 till +230, max +250 | |

Color: | Transparent grey | Transparent white |

Surface: | Smooth | Smooth |

1: For membrane vacuum presses, there is now a trend towards our high tear strength thermoforming rubber sheet (DH2211), which is really gaining in popularity among our customers.

2: “Give the people what they want” – Custom-made thickness, width and length are available.

3: The color does not impact the quality; it is really just to make it easier to distinguish different material durometers or product characters.

Technical Data Sheet – DH2211 Silicone Rubber sheet (Smooth/Smooth) |

Area of application:

Laminating of foil, veneer, production of triplex, thermoforming of solid surface and thermoplastic materials.

Vacuum laminating and forming using a single mold

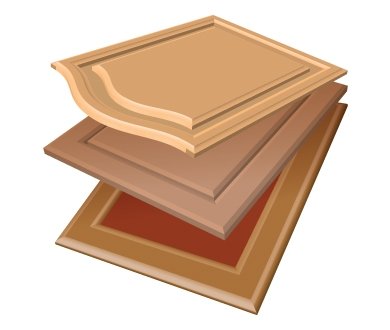

* furniture components

* interior finishing and fit out components, cabinetry

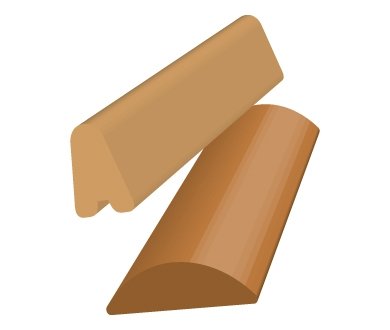

Wrapping profiles and paneling

Soft forming

veneering of raised door panels and suitcase fronts

Veneering & Laminating

veneer application/most material to shaped elements

DEER HUNTER – MAKE YOUR SOLID SURFACE IDEAS COME TRUE

Vacuum forming rubber sheets are ideal for various woodworking projects, offering a range of advantageous properties. Our selection of membranes provide high durability, good temperature resistance, and excellent elongation capacities to enable precise shaping and molding. Used frequently in lamination processes in the aerospace or automotive sector and beyond, these components are perfect for vacuum pressing tasks involving wood or other solid surfaces.

Visit our page for more details on product specifications – our specialists will be available if you have any tailored queries!

High-volume sheets

We offer high-volume silicone rubber sheet for large moulds and components to press up to 1 m height. Please contact us for tailored advice.

IN STOCK – Available per linear meter

Thermoplastics

2D and 3D plastic sheet vacuum forming and pressing.

Automotive

Wrapping or covering car dashboards, wood veneering of car panels or trims and laminating car side panels or covers.

Sublimation

Large format sublimation of hard substrates and sublimation and thermoforming of solid surface and thermoplastic materials.

Composite

Hot vacuum pressing and forming of multiple fiber layers.

Woodworking

Bent laminations and form veneering, flat pressing of panels, wood veneers and decorative laminates, veneering profiles, and high-strength bondings.

Solid Surfaces

Preheating and vacuum forming or pressing of solid surface and similar materials.

Rigid Thermofoil

2D and 3D foil lamination of moldings, e.g. MDF panels, profiles, kitchen fronts.

Below we will see what happens when our customers put our silicone rubber sheets on their vacuum press machines:

1

2

3

4

5

6

You'd Like To Learn More

Become A Partner

We are well prepared to work with you tegether!

No matter who you are and what you do, a wholesaler, distributor or end-user, we are always looking out for new partnership chances. Submit an application today and our sales team will get back to you as soon as possible within 24 hours and help you select the right silicone bag you want.

- fullchance100

- 0086 13823789007

- exporting@cndeerhunter.com